March 2023

Challenge:

Seadraulics (formerly Specialist Offshore Services) required structural, piping & geotechnical engineering design support to deliver the structural “module” component of their SHFM design. The SHFM subsea structure had demanding specifications such as deployment to seabed at (-)4000m, electrical/hydraulic ROV interfaces, 2 x chemical dosing bladders, flooding system & filters, loading arm and pressure testing facilities.

Cube Scope:

- Structural design in accordance with DNV 2.7-3 / AISC 360-10

- Piping design to ASME B31.3

- Geotechnical design to API RP 2A / DNV-RP-C205

- 3D interchange of CAD files between mechanical and structural models and Inventor / Solidworks for full clash check

Outcome:

Critical file management of the 3D Mechanical models in Inventor and Structural models in Solidworks for weekly integration and clash checking allowed for a seamless design process. Structural design incorporated Chinese steel sections for COOEC fabrication. No clash problems with fabrication as a result of integrated approach to combined 3D module models.

November 2021

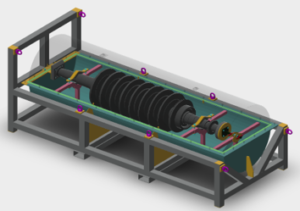

Woodside’s gas compression trains up in Karratha are key to their continuous delivery of NWS gas to customers. In order to keep it that way, critical spare rotor shafts must be available and is a preserved condition for whenever needed. To ensure that this happens, Cube Offshore developed, manufactured & tested a range of 5no. dedicated Rotor Cocoon Skids designed for the following criteria:

- Rotors secured inside cocoons using adjustable restraints

- Pressurised containment of Nitrogen gas inside cocoons to preserve rotors

- Horizontal lifting, upending and vertical lifting (Woodside & DNV 2.7-3 specifications) c/w rotor under pressure

- Road transport & forklift handling

5no. Rotor Cocoon Skids in vertical storage position:

Vertical lift of Rotor Cocoon Skid due to careful lift point placement:

Rotors secured inside cocoons for all loading scenarios:

Progress photo during manufacture:

Rotor Cocoon Skids – 3D CAD model representation:

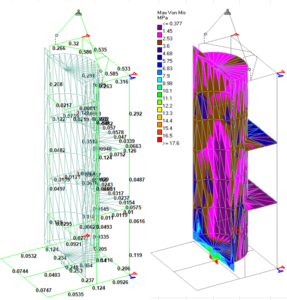

Vertical lift analysis extract showing plate stress and member utilisations:

July 2020

Challenge:

As part of the INPEX Ichthys phase 2 drilling campaign, the Casing Setback Area needed to be raised by 1.5m. Design loading was 436t, no offshore hotwork allowed, the platform was to be easily removable and overhead lift access on the rig was restricted.

Scope:

- Interface with INPEX and Maersk Drilling stakeholders to resolve BoD & concept

- Concept development & detailed design for operating & installation load cases

- Manufacture & testing of 3no. casing Setback “pods”

- Design, manufacture & testing in accordance with DNV 2.7-3

- Certificates of Conformity for Lifted Equipment

Outcome:

After early liaisons with INPEX & Maersk Drilling personnel, a comprehensive Basis of Design was agreed and a 3-part “pod” concept developed to aid both functionality & installation limitations. The individual “pods” were safely lifted into position then connected together to form a single Casing Setback Platform. No hotwork was required for the installation of the platform and lifting analysis for a vertical lift and side lift provided for lifting options. Cube further proposed that all timbers be pre-installed & secured which greatly reduced offshore installation risk & effort.

Offshore Lift

Client feedback:

Great work all and thanks to Andrew, Emily and Steve especially for coordinating. That was a great late in the day call to pre-install the wooden blocks.

Malcolm Reid

INPEX Drilling Superintendent

December 2016